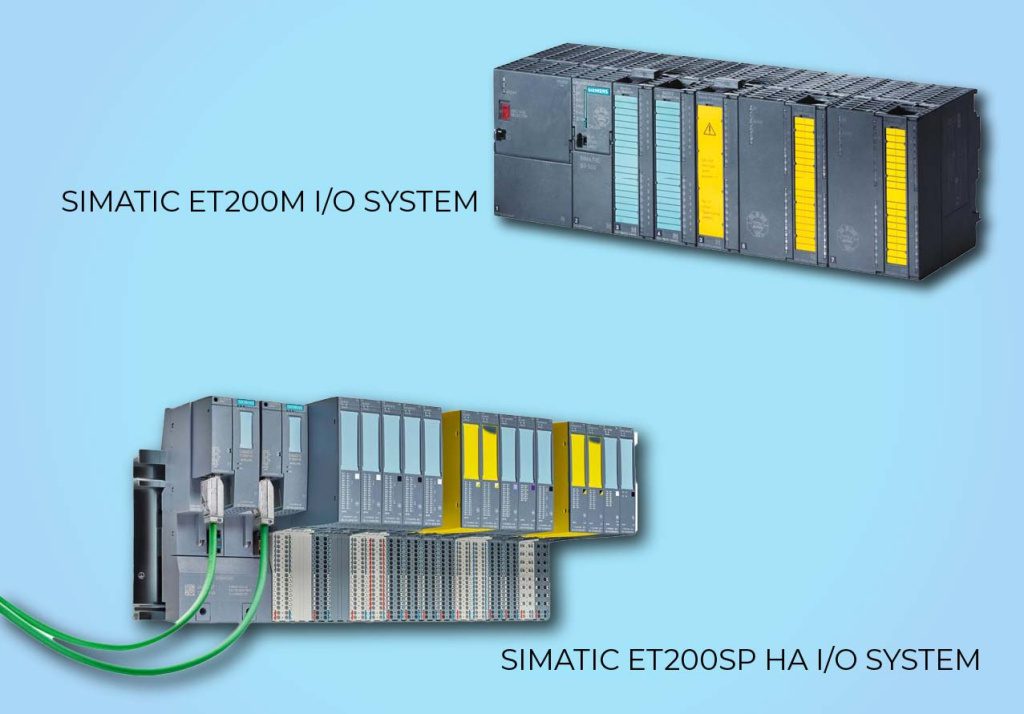

If you’re still running a SIMATIC ET 200M I/O system, here’s the reality:

It’s time to move on. Not because it’s flashy. Not because Siemens said so. But because it’s already putting your operations at risk.

As of October 2025, Siemens will no longer accept orders for S7-300 and ET 200M components. That means:

- No new hardware.

- Limited support.

- Scarce spare parts.

Still debating whether now’s the right time to act? Here’s what your team might already be experiencing—and what’s coming next.

The Real Cost of Holding off

Here’s what plant teams are already experiencing with aging ET 200M systems:

Parts Are Running Out

As Siemens phases out the product line (with final orders ending in 2025), companies everywhere try to get by cannibalizing parts from one plant to keep another running. That’s not a strategy—it’s a short-term patch.

“No more parts are coming. They’re done making them. What you’ve got is what you’ve got.” – Field engineer.

When a module fails, you’re stuck hunting down used components—or worse, risking downtime while you figure out the best solution.

Maintenance is Slower and Riskier

Legacy systems come with:

- Outdated documentation

- Limited diagnostics

- Configurations few people want to touch

Even basic tasks like wire termination or module replacement become more stressful, especially when:

- You’re unsure who last touched the config

- Every move could trigger a new fault

- The person who initially set it up is long gone

Your Talent Pool Is Shrinking

Your most experienced controls engineers may be retiring—or already gone. Newer engineers? They’re trained in TIA Portal and modern platforms, not legacy hardware.

You’re not just losing parts—you’re losing the people who knew how to use them.

Simulation & Digital Twin? Not with Legacy IO

Modern simulation platforms like SIMIT or digital twin technologies are not backward compatible with legacy I/O. Even if they are today, future updates will phase them out.

“New versions of simulation platforms won’t support ET 200M. If you’re not upgrading, you’re locking yourself out of the future.”

Want to test changes offline, validate updates in advance, or optimize commissioning time? You’ll need modern hardware to do so.

Why Teams Still Wait to Upgrade

Even with all the risks, hesitation is common—and totally understandable. Here’s what we hear most, along with some ways to think differently about each concern:

“We don’t have the budget this year.”

We hear this a lot. Capital budgets are tight, and upgrades compete with production, staffing, and safety investments.

Here’s another way to look at it:

You don’t have to replace everything at once. Many teams phase upgrades over multiple quarters—starting with the most critical areas. Setting aside a small portion of next year’s budget can give you flexibility later.

“We’re worried about downtime.”

No one wants to shut down production unnecessarily. Especially not when schedules are full, or margins are tight.

Here’s another way to look at it:

Waiting increases the chance of unplanned downtime—which tends to be longer, harder, and more expensive. Even in small phases, planned downtime puts you in control of the when, how, and how much.

“We’d have to rewire thousands of connections.”

That’s a fair concern—especially with legacy panels. Rewiring takes time and labor and introduces room for error.

Here’s another way to look at it:

Siemens offers adapter solutions that let you reuse existing wiring. Even if a complete rewiring is needed, many teams break it up into planned outages or handle it during regular maintenance windows.

“Our current system still works—for now.”

And that’s great—until it doesn’t. We’ve seen legacy systems work fine right up until they don’t.

Here’s another way to look at it:

When it fails, how quickly can you recover? How easily can you source parts? The cost of being reactive often outweighs the cost of acting with a plan.

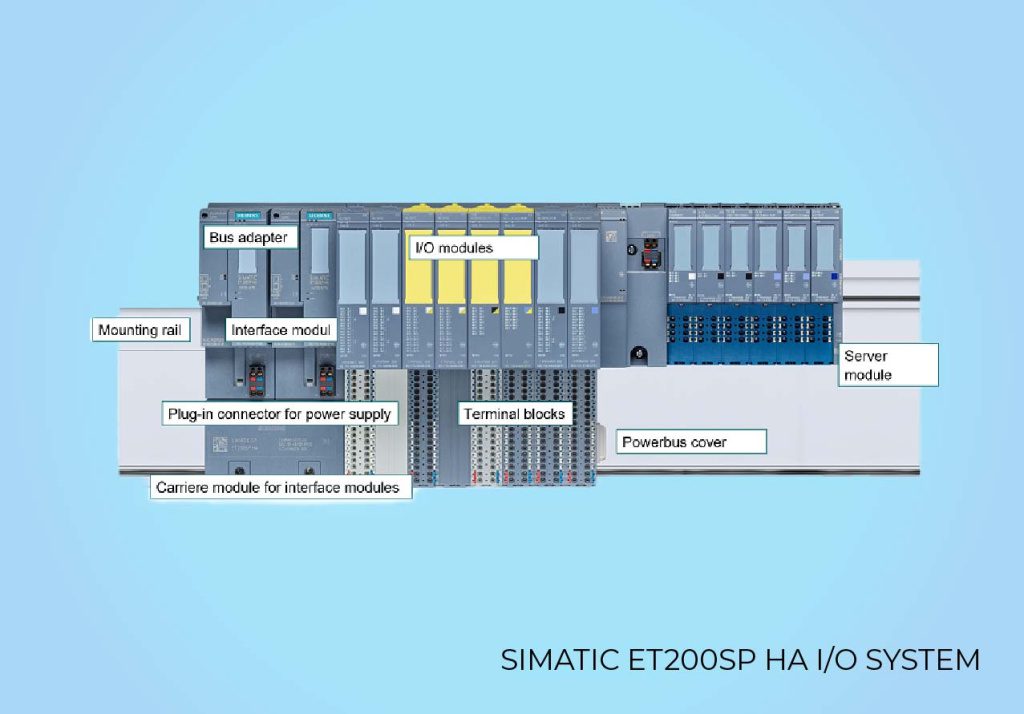

Why Teams are Choosing ET 200SP HA

The SIMATIC ET 200SP HA is the modern replacement built for high-availability operations. It’s compact, powerful, and ready for today’s challenges:

- Hot-swappable modules

- Redundant power and communications

- Integrated diagnostics

- Full compatibility with PCS 7, PCS neo, and TIA Portal

It’s not just a hardware refresh. It’s the foundation for reliability, visibility, and future-ready automation.

Let’s Talk About What’s Next

At Pigler Automation, we help industrial businesses navigate ET 200M migrations with confidence. Whether you need a rapid turnaround, a phased approach, or help to make the business case—we’re here to support your goals, not just sell hardware.

Your system is not just aging—it is actively limiting your ability to grow, support, and modernize.

Let’s assess your upgrade path—before parts and time run out.