Addressing Climate Change Through Carbon Capture

In 2021, Global Thermostat, a trailblazing carbon capture innovator, embarked on a journey to revolutionize how industries tackle carbon emissions. Focused on designing and developing cutting-edge technology that extracts CO2 emissions from the air, they sought to offset their carbon footprint and catalyze a broader, industry-wide transformation. Global Thermostat recognized the untapped potential for their groundbreaking technology within sectors such as Synthetic Fuels, Industrial Gases, Energy, Food and Beverage, and much more.

CHALLENGE

Turning Concept ino Reality

The challenge for Global Thermostat was the idea of marrying their state-of-the-art carbon capture equipment with an advanced control system like Inductive Automation’s Ignition. Starting with a lab-sized pilot system, the aim for Global Thermostat was to scale up to a full-sized plant and in the process validate their hypothesis: carbon emissions could be effectively and economically removed during the refining or manufacturing process.

SOLUTION

Innovation in Action

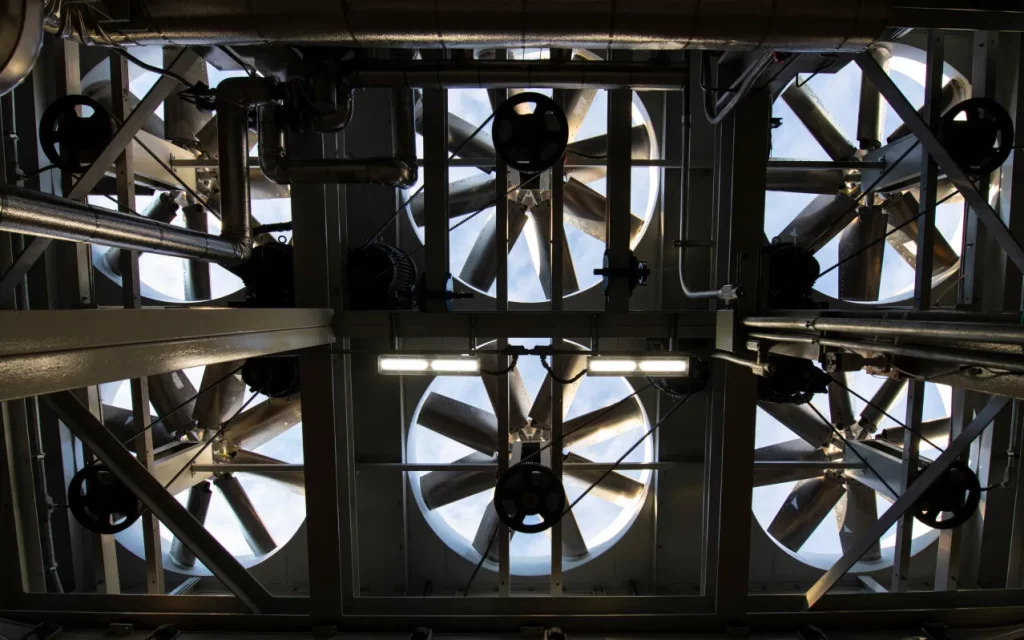

Pairing TIA Portal PLC with Inductive Automation’s Ignition HMI system, we took advantage of Ignition’s many features, such as OPC compatibility, user-defined templates, and vision clients. The OPC compatibility allowed for ease of communication between the PLC and Ignition HMI. Ignition’s UDTs (User-Defined templates) streamline standardizing custom blocks into a library object, allowing our engineers to create a custom block library and bulk updates objects as needed. The HMI Visualization Client Software provided easy access to the project locally and remotely, allowing for unhindered accessibility to plant personnel. Additionally, our engineering team developed a simulation platform to facilitate extensive testing within a controlled environment before scaling up, ensuring successful integration while optimizing efficiency and safety.

OUTCOME

Paving the Way for Change

Applying the concepts developed with their pilot plant, Global Thermostat was able to successfully scale up to a full-scale plant, equipped with CO2 capture technology and powered by Ignition. The new plant has the capability to remove 1,000 tons of CO2 annually and Global Thermostat continues testing and fine-tuning the system to identify optimal conditions for carbon capture.

Partnering with Pigler Automation, Global Thermostat realized its goal of turning a lab-sized pilot plant into a full-scale plant capable of removing CO2 emissions during plant operations. Working together, we are helping to envision a future where this technology is used across industries.

Case Study: Transforming Carbon Capture to Improve the World

Download the the full PDF of our Case Study